We specialize in delivering comprehensive lighting solutions for corporate clients and dealers. With a focus on quality, customization, and innovation, we’re your trusted partner for all lighting needs.

As one of the most professional manufacturer of automotive light, M&F started business since 2010, and built the production line since 2013.

In order to assure the product quality and stability, we’ll arrange comprehensive tests for mechanical, electronic, and optical performance, and our factory strictly controlled the production process according to ISO9001 standard, and 100% inspection on each light before shipment.

Besides, all of our products could get Emark approved. And most of them are according to CISPR CLASS 4, FMVSS 108.

We’re committed to offer affordable, exclusive and high quality products to customers in the world.

Doing the right thing for customers is our core value, we insist on working with trust, honesty, integrity and responsibility.

We provide end-to-end professional lighting solutions tailored to your business needs. From design and production to customization and support, we deliver innovative and reliable lighting systems that enhance efficiency and performance.

For avoiding fierce competition and increase the competitiveness, we are willing to help you to develop new module if you have design idea, and we will share module cost with you, besides, Exclusivity could be sent to you if you need.

For our VIP customers, we will provide free samples you are interested in.

For our VIP customers, if you have demands of brand promotion, we can laser your brand logo onto lights as you required.

For our VIP customers, if you have demands of brand promotion, we can help you to design brand colorful box when the single type quantity reach 500pcs.

Our sales team will provide some market suggestions to you according to our serving customers experience in your area or same type with you.

We are responsible for each light, our sales team will solve your concern before ordering shortly and answer your complaint when you get defective lights within 2days, after checking, we will refund your payment. Any questions for business or cooperation are welcomed.

With over 10 years of experience in LED lighting for automotive and off-highway equipment, M&F provides customized, high-quality solutions. Our tailored designs and reliable performance drive client growth and success.

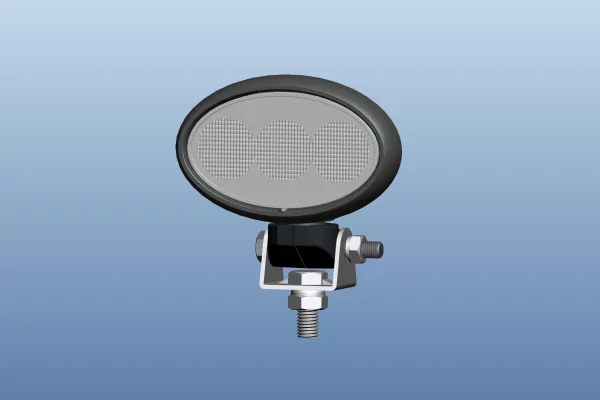

Products

Company Information

We will respond to your message within 24 hours.