Tailored lighting solutions designed with precision. We bring your vision to life with custom designs that align with your unique business needs.

High-quality, efficient manufacturing that delivers reliability. Our products are built with cutting-edge technology for maximum performance and durability.

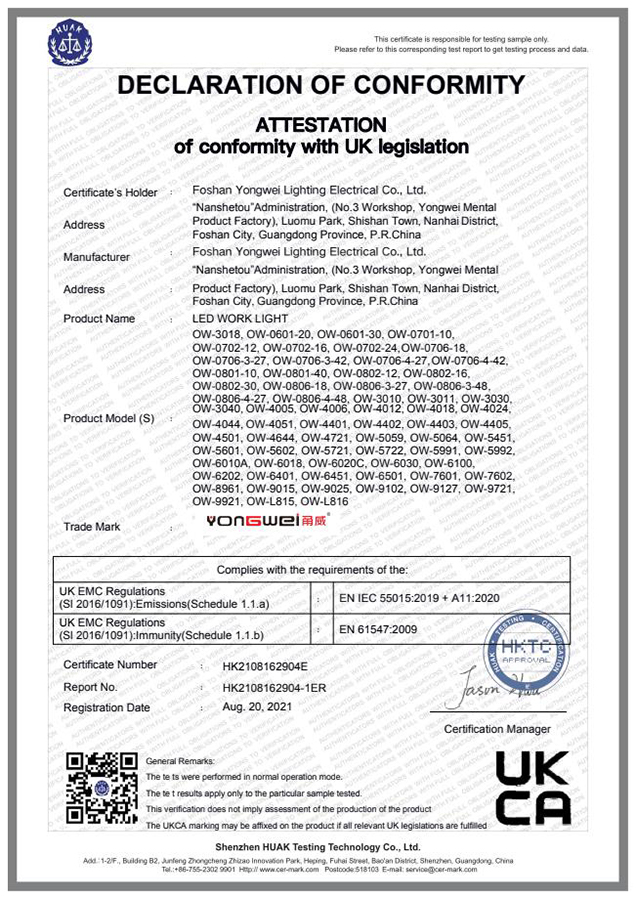

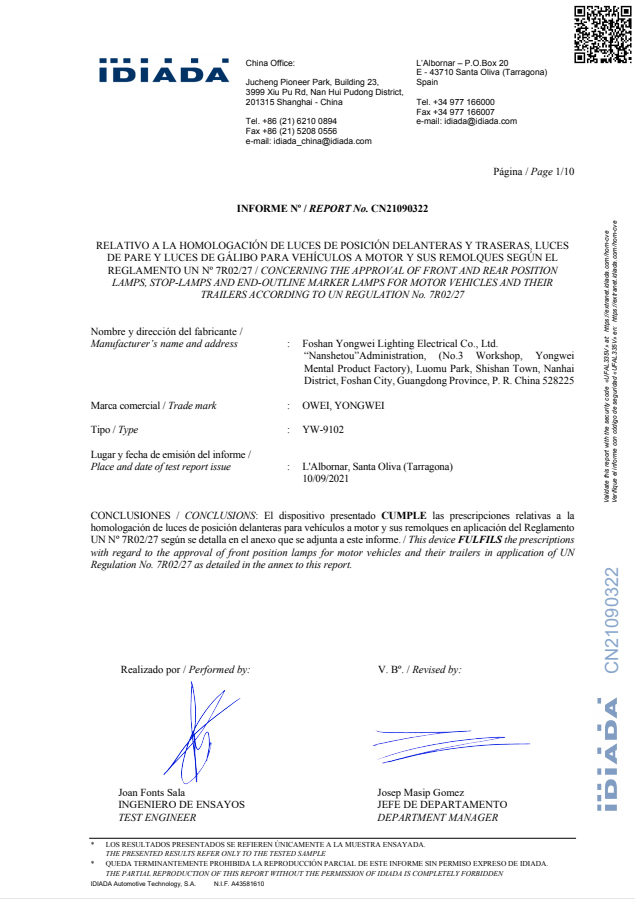

Rigorous quality control for uncompromising standards. Every product undergoes thorough testing to ensure safety, efficiency, and lasting value.

M&F Lamps is a subsidiary brand, with factory and export brand separated, we could offer you not only factory direct price, product & financial support, but flexible support with fast reactions.

R&D engineer team are professional in mechanical, electronic and optical solutions for LED work lights. Our CISPR 25 CLASS 4/5 solution will assure the brightness, stable and lifespan of our products.

High level quality standard on LED work lights, driving lights and headlights, Stable material supply chain based on our steady growth of sales volume, Strict management according to ISO9001 & IATF16949 quality system.

Our LED work lights production process at MFLamps adheres to the highest standards, having received ISO9001 and IATF16949 certification, ensuring top-quality manufacturing and consistency.

-证书扫描加化学.jpg)

We’re both. Frankly speaking, as a subsidiary brand specialiazed in LED work lights for off highway equipments, we mainly exported the products of our own factory, but sometimes, we also help customers source some parts.

What we believe is that your business is also our business, and what we want to do is to expand the market with you together by developing innovative new products, reducing your potential losses, and save your cost, include product, time, and communication.

Firstly, we’ve specific definition on our quality standards, and in order to fullfill these quality requirements, we’ll arrange comprehensive tests for mechanical, electronic, and optical performance, include optical parameter test, vibration test, EMC test, salt spray test, high & low temperature test, waterproof test, aging test, beam pattern test, and beam angel test etc. All products could be released on the condition that pass all these essential test.

Besides, we have a strict QC system according to ISO9001:2005, all the materials would be inspected before production, include material housing, reflector, lens, PCB, LED chips and brackets, screws etc.

In the process of mass production, our experienced QC team inspect products by checking the current, waterproof, lifespan and appearance etc, and each led work light or driving lights should be approved for strict inspection, and ensure that there is no defect such as moisture, LED getting darker, or working improperly before shipment.

If there is any quality problem when customers use it, we’ll collect all the detail information and discuss it on the meeting, and the case would be showed on the Defect Mangement Board in workshop, so that every staff could keep two eyes on the mistakes and improve our quality level continuously.

No, we guarantee that our products won’t have EMI(Radiated and Conducted Electromagnetic Interference) problem. As a professional manufacturer, we set up a high level standard when we design the electronic solution, all the products are according to CISPR 25 standards, and could get ECE R10, R112, R87, R7, R23 approved accordingly.

We guarantee 2~5 years for our products according to customer’s requirements. As our slogan, we design, we make and we take the responibility, we’ll be in charge of it if there is any defectives within the warranty.

Yes, our experienced electronic, optical engineers and sales team will offer you optimal solution and service completely according to your demands.

With over 10 years of experience in LED lighting for automotive and off-highway equipment, M&F provides customized, high-quality solutions. Our tailored designs and reliable performance drive client growth and success.

Products

Company Information

We will respond to your message within 24 hours.